Plastic Recycling – Gateway to Net Zero

There has been a lot of effort in trying to both find new innovative materials as well as producing products from recycled materials. Unfortunately, as of today, neither of those approaches has been sufficient. Typically, mechanically recycled plastic products have lower value-add whereas using biomaterials in mass production poses a threat to our planet's capacity from food security perspective.

Another significant challenge is in waste collection, especially in the developing countries. It has been estimated that 50 million tonnes of plastic waste can be found in nature, and the volume is estimated to grow by 10 million tonnes per year. This coupled with the expected increase in the consumption of plastic until 2050 poses a huge environmental challenge for mankind. While a huge number of humans contribute to this environmental disaster, it has been difficult to find anyone to pay for the cleanup. Fortunately, these activities seem to be gaining in popularity.

Even though the situation, in terms of waste capture, is significantly better in the developed countries, the recycling rates are insufficient. Of the 8.3 million tons of plastic waste humankind has produced, only 9% has ever been recycled. And combined with the downcycling nature of mechanical recycling, there are certain limits to what is the optimal fraction of plastics that should be mechanically recycled.

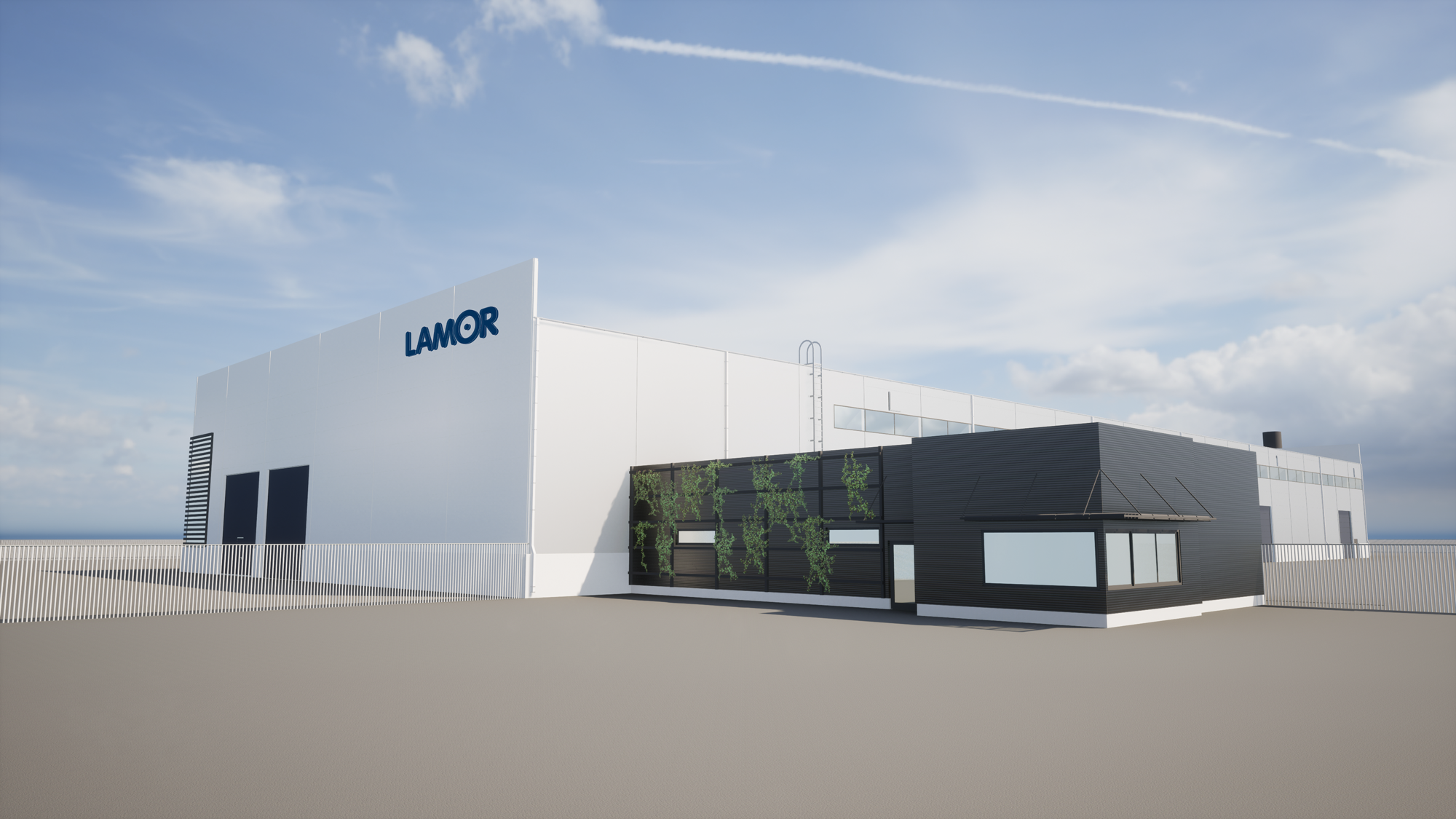

Our pilot project in Kilpilahti, Porvoo is the first industrial scale chemical recycling facility for plastics in Finland. We aim to turn plastic back to valuable raw material. The liquid produced from plastic waste works like virgin fossil raw material in the production of new plastic. It is suitable for many purposes for which mechanically recycled plastic granules are not suitable: these are, for example, food packaging that requires perfect hygiene. The facility includes two main processes: first the plastic is shredded in pre-treatment and then combusted without oxygen in the thermochemical process. The liquid is processed and delivered for further refining to meet the requirements of the petrochemical industry.

Using less single-use plastic while increasing the efficiency of plastic waste capture, and both mechanical and chemical recycling are all important steps on our way to net zero. To succeed in our journey, we need to co-operate throughout the whole value chain. Plastic manufactures will need to produce more recyclable products, consumers need to sort their waste more efficiently and the waste management industry will then do their part to bring the plastic waste back to life.

This is a challenge that we need to tackle together.