Betolar will begin replacing cement in the world’s largest market in Asia

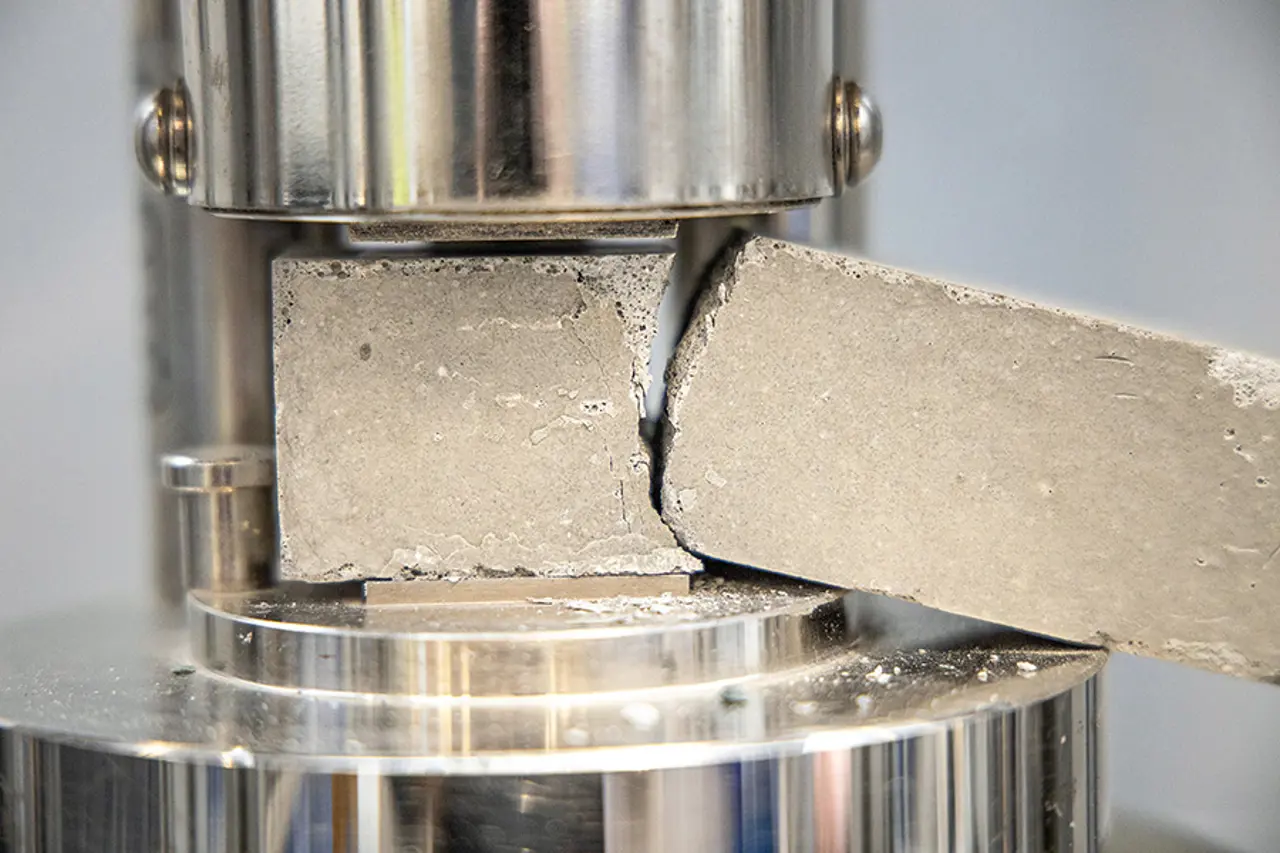

Concrete is by far the most widely used building material in the world and one of the largest emitters of climate emissions. Betolar offers a solution for the most climate-damaging stage of its production: cement manufacturing.

“In Asia, our clients replace cement with, for example, blast furnace slag from the steel industry or coal power plant ash. The main application is yard stones and cinder blocks, which are in huge demand, especially in India”, says Melina Pinomaa, communications manager.

Betolar Team Vietnam: Matias Heinänen, Thuan Pham and Janne Niskanen

Photos: Betolar Oyj

The artificial intelligence developed by Betolar can be used to determine how the raw materials from the by-products of other industries and the concrete aggregate interact with each other, and with what mixing ratio they give the desired result. The company offers its clients, i.e. concrete plants, a recipe and supports them in the transition to a new manufacturing method.

What makes the business model highly scalable is that concrete plants can switch to a new manufacturing method with very little investment.

On a purely commercial basis, the company's Geoprime recipe already produces concrete yard stones, lamp post bases and sewer pipes in Finland, Denmark and Belgium.

However, the world's largest concrete market is in Asia. With Business Finland's Developing Markets Platform funding, Betolar has established partnerships in India (the world's 2nd largest concrete producer), Vietnam (3rd largest) and Indonesia (6th largest).

“The project funding has helped engage potential clients on a common development path and created a financial incentive for it. However, refining and testing the recipes takes a lot of time”, says Melina Pinomaa.

Pinomaa estimates that the commercialisation phase in India and Vietnam will come in the second half of 2022. In Indonesia, progress has been slower due to prolonged Covid lockdowns.

It was a great help to us that Business Finland's local offices had a good understanding of qualified market researchers.

The progress has been dramatic, as market surveys in Asia were started only in 2019. In the meantime, the world has experienced a pandemic and local recruitment had to begin without physical meetings.

“It was a great help to us that Business Finland's local offices had a good understanding of qualified market researchers. After the interviews, the most suitable ones were selected. It saved us time”, says Pinomaa.

Learn more about Developing Markets Platform funding